The

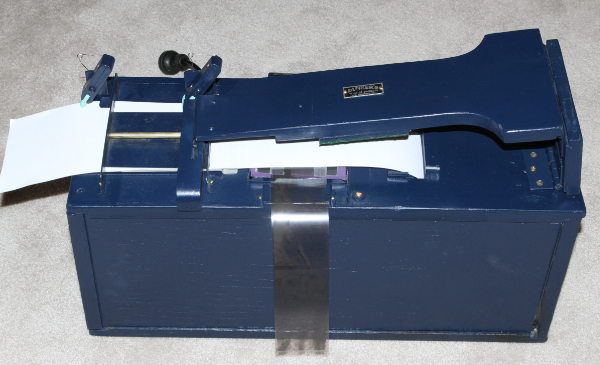

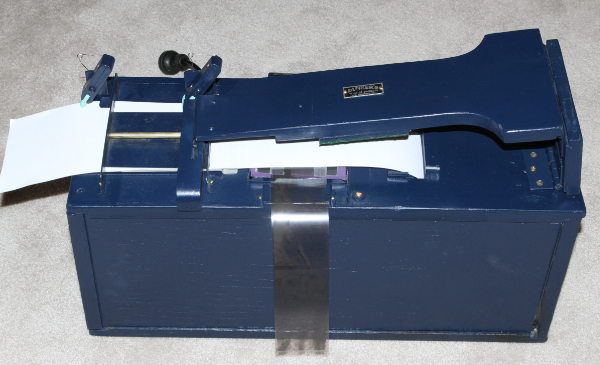

following drawing and detailed explanation of the operation of Vincent

Dunker's contact printer were graciously provided by his grandson, Leo

Pruneau, of Woodend, Queensland, Australia. Leo Pruneau has

previously held many high-level positions in automobile manufacturing

including director of design for GM's Australian subsidiary, General

Motors-Holden's Ltd. As design director, Leo was responsible for

many of the beautifully styled Holden automobiles which are now admired

by automobile enthusiasts around the world. (see Vincent Dunker's

biography at http://dchis.com/Dunker%20Biography.htm, or click on the blue lettering below Vincent's photo on the 1950s page.

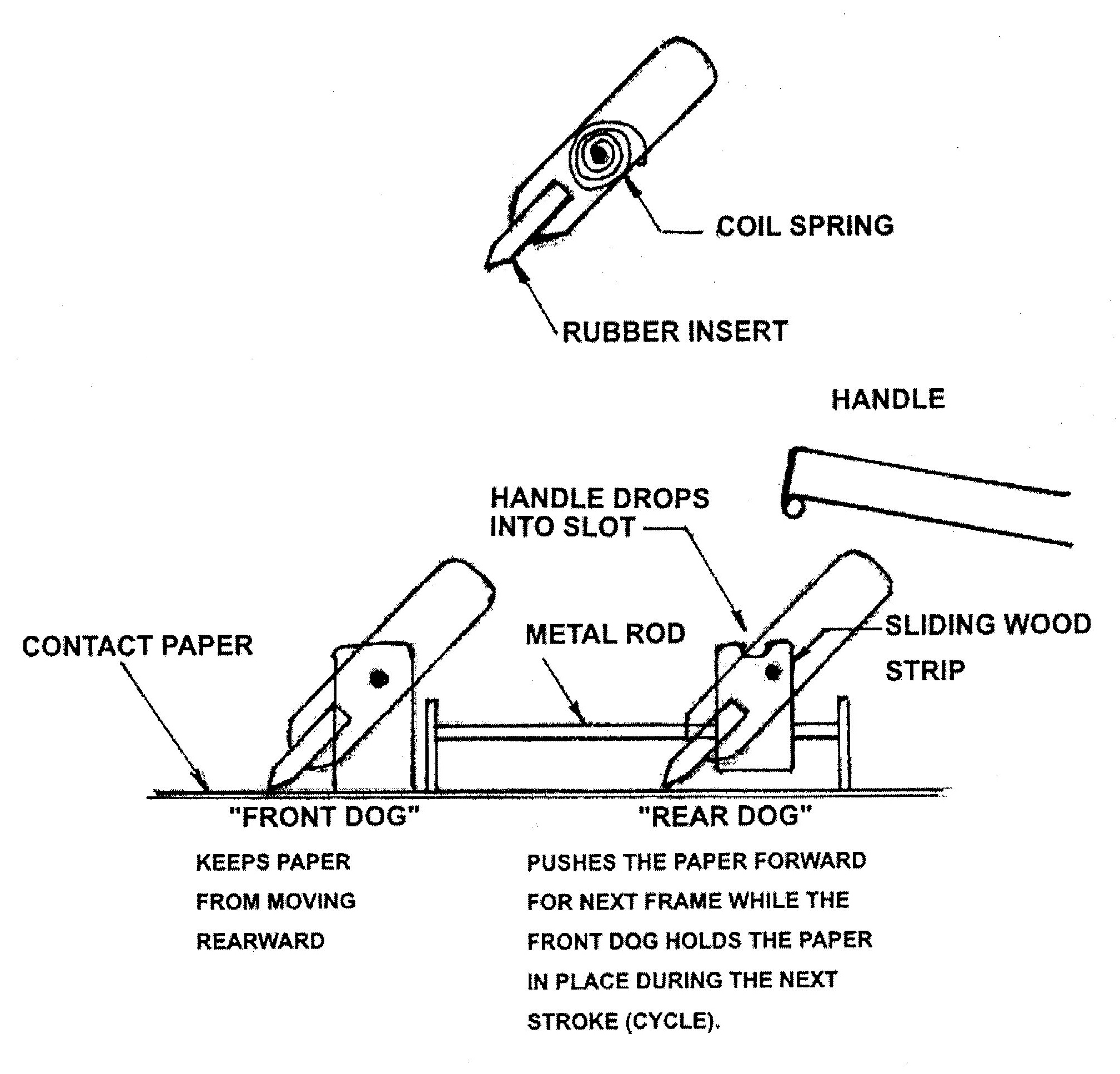

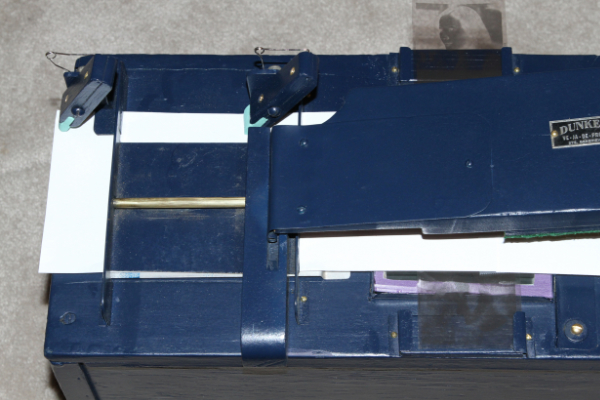

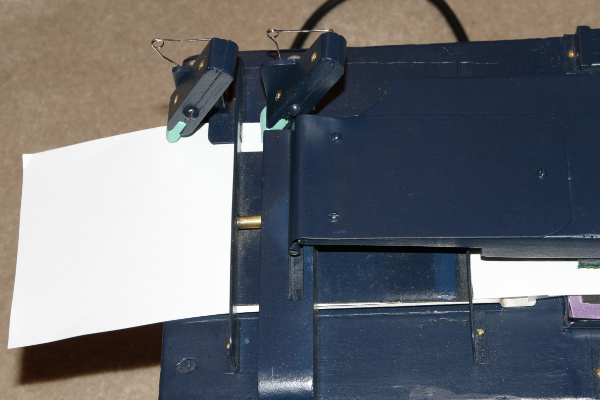

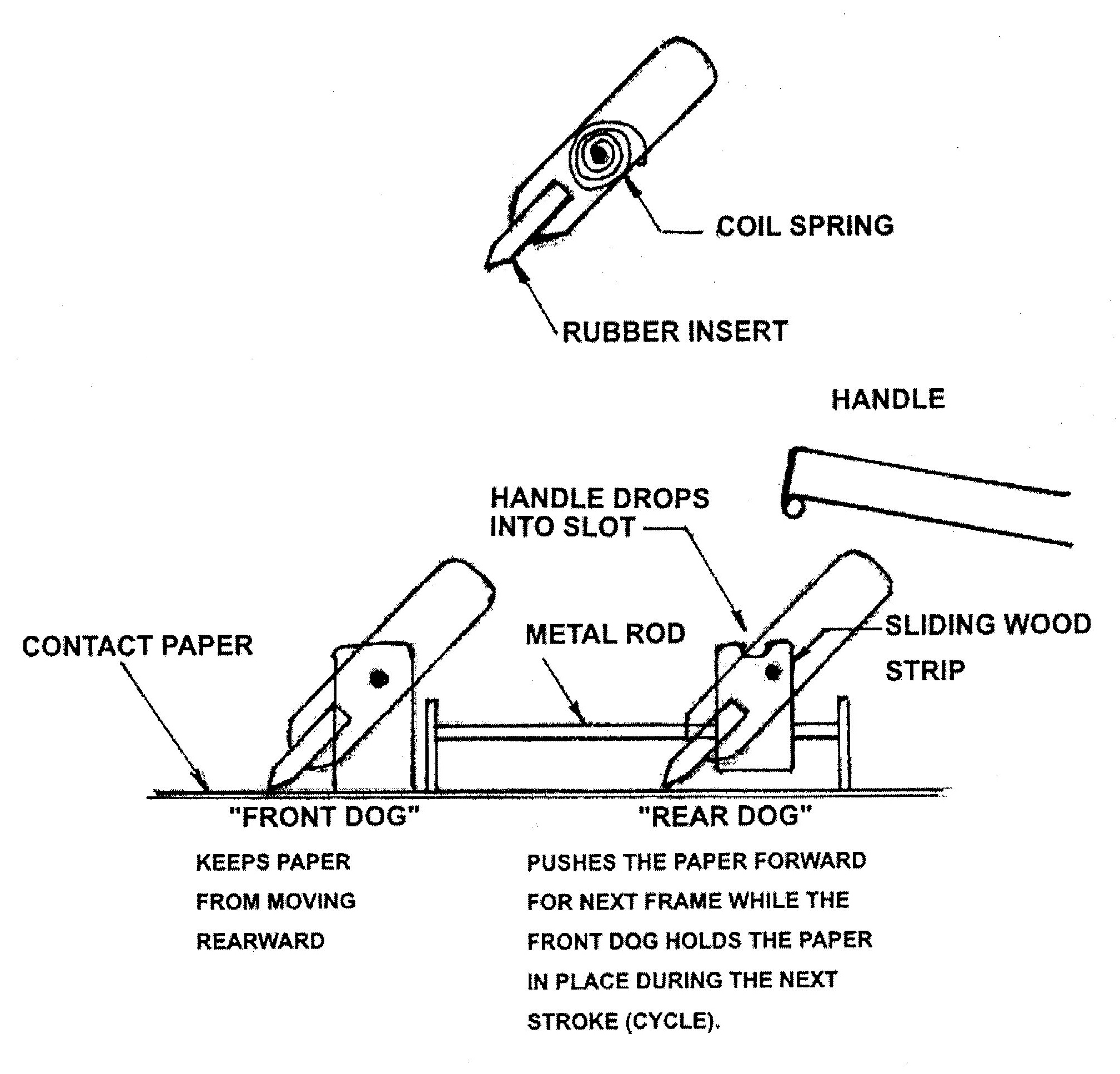

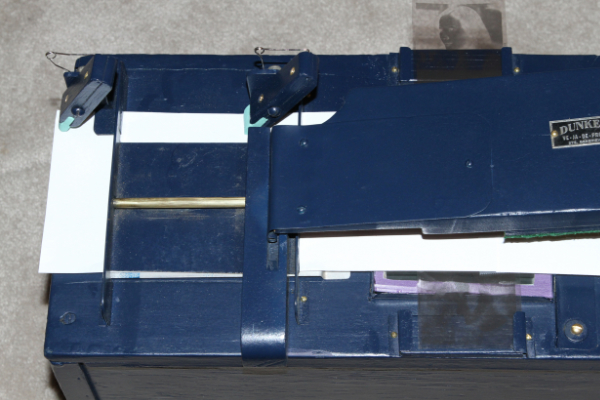

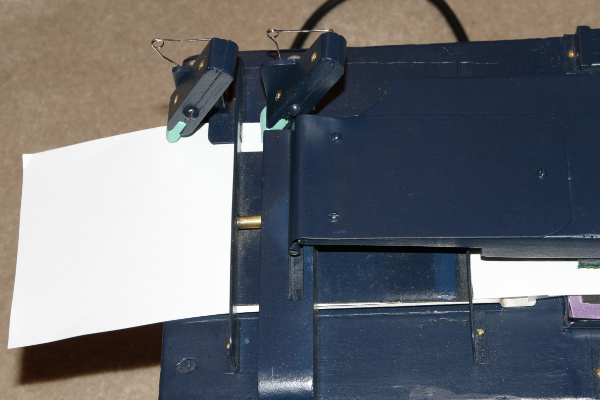

1. Sliding bar at the right (with handle in place) before

handle is moved downward 2.

Sliding bar moved left by downward motion of handle advances print paper

The apparatus described above is

the contact printer’s primary feed and control mechanism, and is

an important part in the functioning of the printer. It works in

the following manner –

From the roll, the contact printing paper is fed between the

aluminum plate and the blue metal plate, and under the front and rear

slotted components (DOGs) to the side, located on the top of the

printer box.

When the handle is operated, activating the rod-mounted wood

strip, to move it forward and backwards the DOGs work in combination

with each other. The rear DOG, attached to the wood strip, pushes

the contact paper forward, while the front DOG, mounted to the printer

box, holds the contact printer paper in place.

Depending on the direction of movement, in the forward motion,

the rear DOG's ‘rubber-tip’ wedges against and grips the

contact paper to push it forward. On its backward movement, the

rubber tip – because of the angle and the bevelled end shape

– slides over the contact paper without gripping it.

Conversely, the front DOG functions in the opposite manner.

Due to the angle of the rubber tip, and its bevelled end shape, the

contact paper slides forward without being gripped. However, it

cannot move backwards because the contact paper becomes wedged against,

and gripped by, DOG's ‘rubber tip’, and held stationary.

The printing of the negative occurs at the end of the stroke,

when the handle is in the flat position, and the two DOGs are closest

to each other. To continue after the negative has been printed,

the wood strip along with the attached DOG is moved backward by the

handle until it stops at the end of the stroke against the upturned

blue metal part. At this stage, the rear DOG, with its rubber

tip, is in position to grip and push the contact paper forward to the

next frame for the printing cycle to continue.

Due to its rapid recycling action, the printer was capable of producing

up to a dozen plus images per minute from a single negative!